Schemc

An alloy based on aluminum with a certain amount of other alloying elements is one of the light metal materials. In addition to the general characteristics of aluminum, aluminum alloys have some specific characteristics due to the different types and amounts of alloying elements added. The density of aluminum alloy is 2.63 ~ 2.85g/cm³, has high strength (b is 110 ~ 650MPa), the specific strength is close to high alloy steel, the specific stiffness exceeds steel, has good casting performance and plastic processing performance, good electrical and thermal conductivity, good corrosion resistance and weldability, can be used as structural materials. It is widely used in aerospace, aviation, transportation, construction, electromechanical, light and daily necessities.

Aluminum alloy is divided into deformed aluminum alloy and cast aluminum alloy according to its composition and processing method. The deformed aluminum alloy is first fused into billets, then plastic deformation processing, through rolling, extrusion, stretching, forging and other methods to make a variety of plastic processing products. Casting aluminum alloy is the blank of various parts directly cast by sand mold, iron mold, investment mold and die casting after melting.

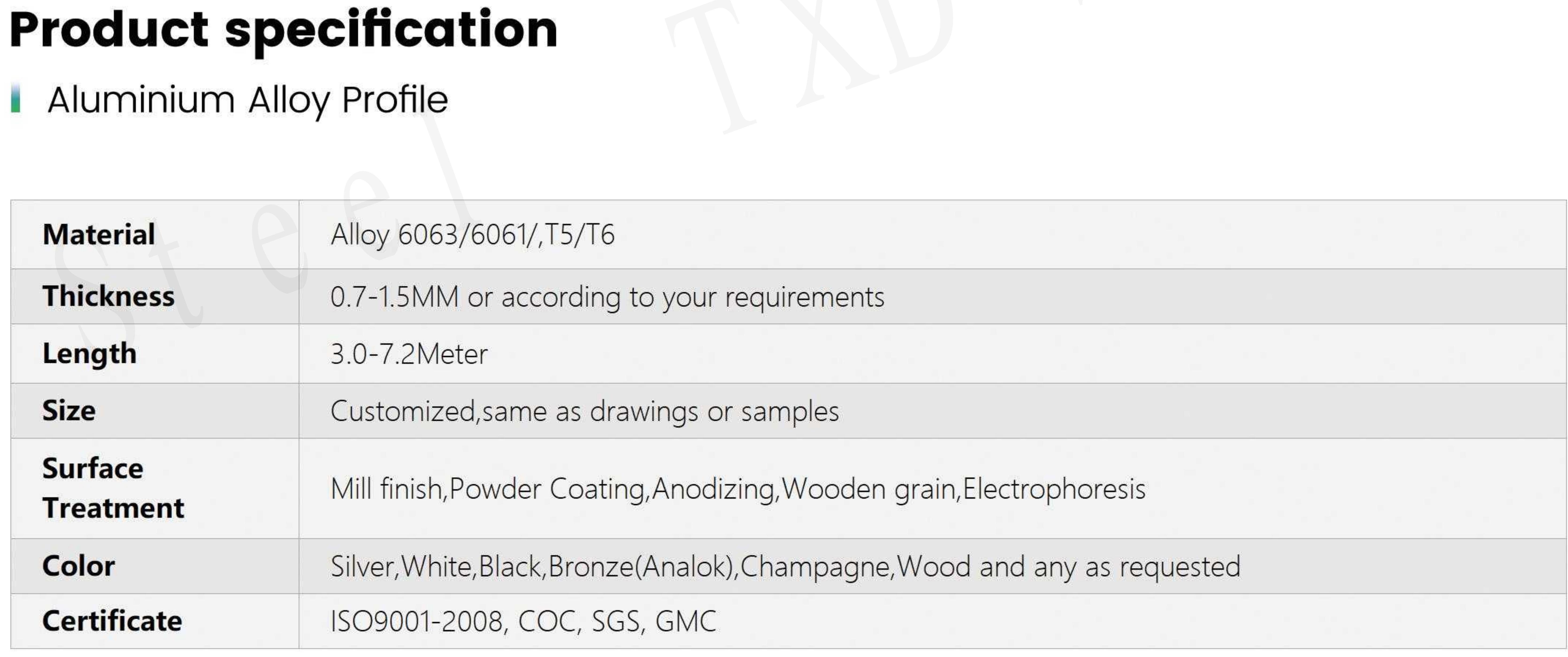

All products can be customized according to the customers' drawings. Surface Treatments for Aluminium Extrusion profile:

Aluminum extrusion profiles are various components made of low-cost malleable aluminum alloy that has been forced through a die. The extensive variety of possible profiles that can be produced make aluminum extrusion profiles extremely useful in the manufacture of countless products on the market today.

Our facilities are certified to ISO 9001:2000 and feature in-house die making facilities, to serve your custom extrusion needs. Using our state-of-the-art technologies to design and manufacturing extrusion tooling allows us to provide you with custom solutions for your unique applications and to ensure that our solutions surpass your expectations.