Schemc

Introduction to Carbon Steel

Carbon steel is the most commonly produced metal today. It is manufactured in a variety of shapes and sizes and is used in most applications of any metal. It is defined as steel with carbon content ranging from 0.05 percent to 2.1 percent by weight. The term carbon steel includes many different grades/classifications, such as low carbon, high carbon, and alloy steels. In general, carbon steel has a higher carbon content, a lower melting point, and greater durability than stainless steel.

Coil - a finished steel product, such as sheet or strip, that has been rolled and then coiled or wound. Based on the experience gained over the years, steel coils are classified into cold rolled steel coils and hot rolled steel coils, or stainless steel coils, carbon coils can galvanized steel according to current products and international standards.

Hot Rolled Steel Coils

Hot rolled steel coils are made from semi-finished products that are rolled, annealed and reduced to a certain thickness and rolled into coils. Hot rolled steel is used to manufacture pipes, steel doors and tanks or further processed into cold rolled steel.

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especially useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter door and automobile's vehicle shell, chassis, door, trunk lid, oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

Hot Rold Rolling

Customers often ask us about the differences between hot rolled steel and cold rolled steel. There are some fundamental differences between these two types of metal. The differences between hot rolled steel and cold rolled steel relates to the way these metals are processed at the mill, and not the product specification or grade. Hot rolled steel involves rolling the steel at high temperatures, where cold rolled steel product is processed further in cold reduction mills where the material is cooled followed by annealing and/or tempers rolling.

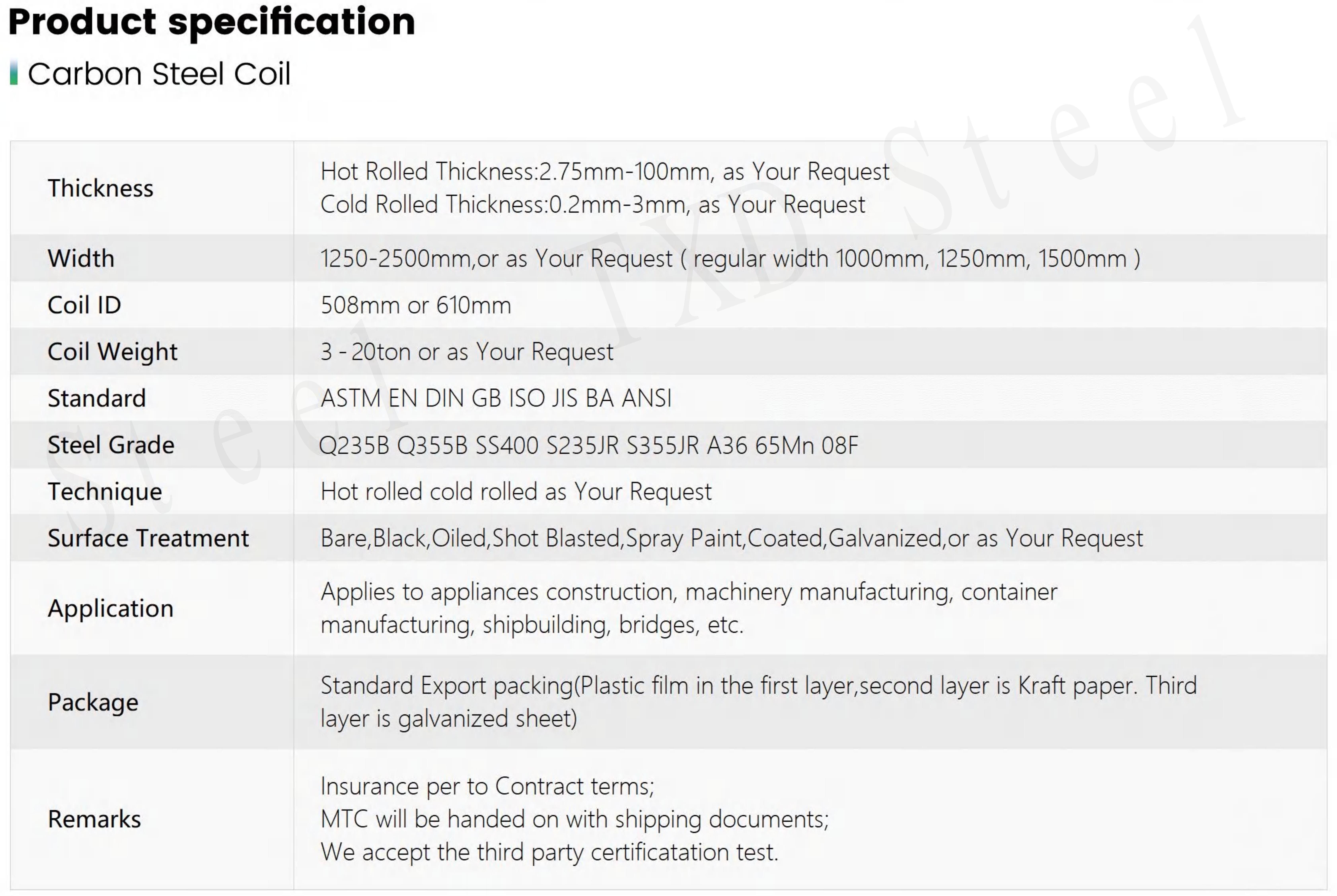

Product specification