Machinery Features

The pipe bending machine is driven by Y (feeding), B (rotating pipe), C (bending pipe), X (left and right displacement of automatic mould changing), Z (up and down changing mould position in seconds), G (rotating mould axis) six-axis electrical servo, with precision roller screw drive, bending precision of 0.05°, feeding accuracy of 0.05mm.

The electric servo drive avoids the defect that the accuracy of common pipe bending machine is affected by oil temperature, suitable for high-load, mass production. Automatic mould changing adopts the principle of the heads Y0, B0, front, left and right displacement to avoid the pipe fitting shaking caused by the displacement of the feeding seat.

The machine head has the function of co-rotation of left and right displacement of the workpiece and some parts with complicated shape, avoiding the defect of replacing the machine to make up the bending of the complicated workpiece of the single-rotation pipe bending machine, greatly improving the precision of the bending workpiece, saving time, manpower and space.

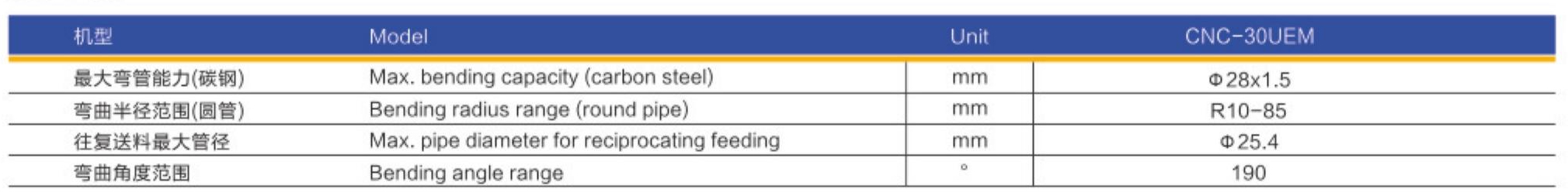

Technical Parameters