Schemc

Stainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications. Stainless steel does not readily corrode, rust or stain with water as ordinary steel does. However, it is not fully stain-proof in low-oxygen, or high-salinity environments. There are various grades and surface finishes of stainless steel to suit the environment the alloy must endure.

Stainless steel is used where both the properties of steel and corrosion resistance are required. Its resistance to corrosion and staining, low maintenance, and familiar lustre make it an ideal material for many applications.

Stainless steel coils are not just the types of stainless steel materials, but instead they are the collection of hundreds of grades and types of stainless steels. Stainless steel coils are most popular variety of stainless steel materials in the world. There are over 40 categories of stainless steel coil grades available making it easy to choose the right one for countless applications and products.

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment and aging treatment before delivery. The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and the internal structure of stainless steel coil. Chromium plays a major role. Chromium has high chemical stability, can form a passive film on the steel surface, isolate the metal from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

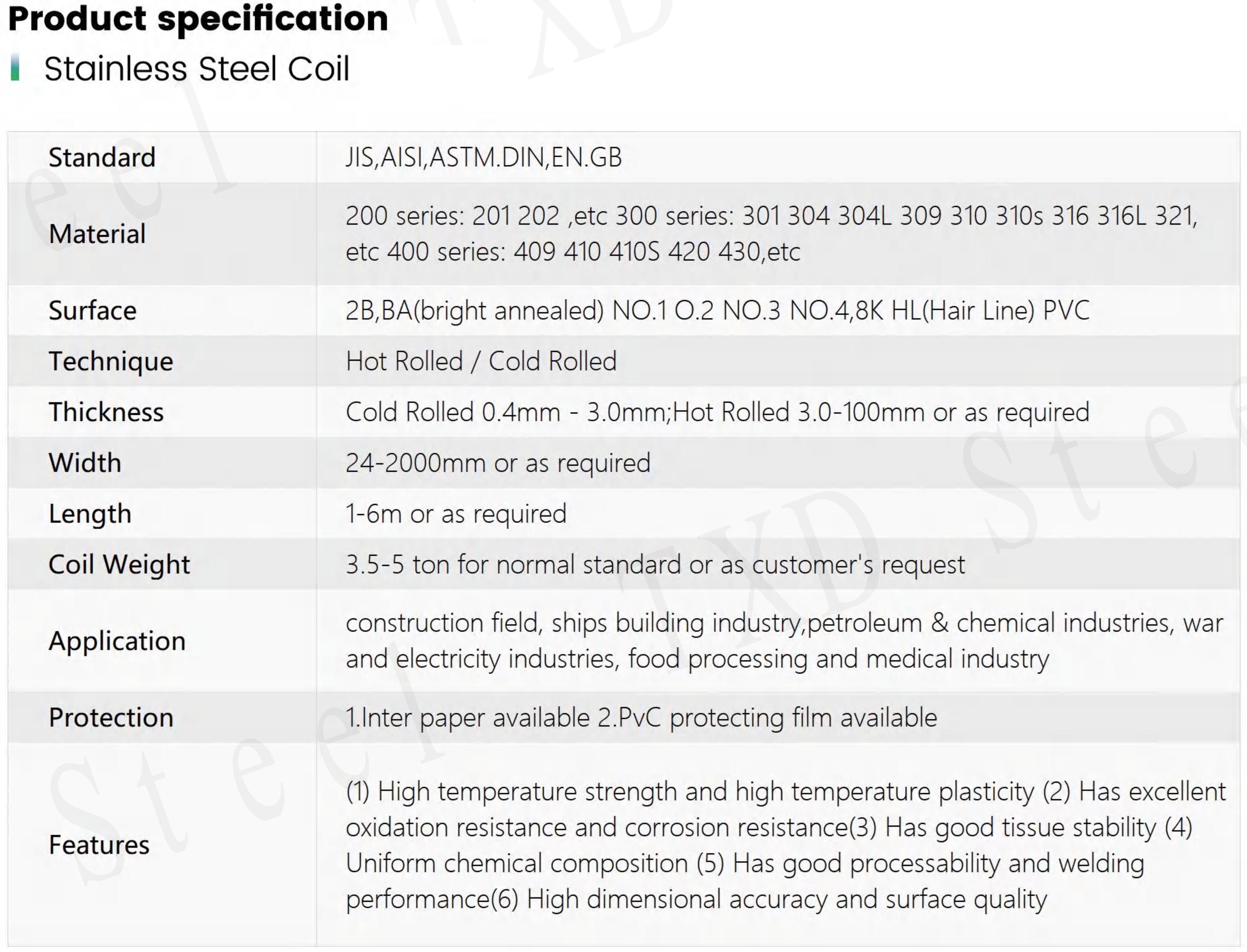

Stainless steel coil can be divided into cold rolled stainless steel coil and hot rolled stainless steel coil according to different production processes. According to the materials, they can be divided into austenite, ferrite and super duplex.

Common use stainless steel coils grades are often represented by digital symbols. There are 200 series, 300 series, 400 series and duplex series. 304, 304L, 316 and 316L stainless steel coils are the most popular and economical grades of stainless steels.

Stainless steel 304/304L coils and stainless steel 316/316L coils, along with duplex stainless steel coils offer good corrosion resistance to many chemical environments as well as marine and industrial exposures.

The finish of the stainless steel coils can be No.1, 2D, 2B, BA, No.4 Hairline, Mirror, etc.

Automotive trim and molding, Difficult-to-form exhaust-system components, tubular manifolds, mufflers, Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps, Gutters and downspouts, roofing, siding, Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers, Oil refinery equipment, oil burner and heater parts, Hot water tanks, residential furnaces, Heat Exchanger tubing, Farm animal pens, Animal shelters, restaurant equipment (hotels), food and dairy processing equipment.